PET bottle manufacturing plant

We are one of China professional plastic injection molding machine manufacturer for all kinds of plastic products, Clamping force from 10 to 3000Ton, injection weight from 20 to 40000g. Also we have CE and ISO9001 certification.

1, Introduction of water bottle preform making machine

The injection molding machine enjoy good reflection from the customers, and own the advantages as follows,

1) Precision: optimized mechanical structure with famous brand controller, greatly increase machine precise.

2) Stable: dual cylinder injection, perform stability and reliability.

3) Durable: platen with DFA design helps to strengthen the rigid

4) Energy Saving: comparing with traditional fixed pump or variable pump machine, it saves electricity obviously.

1) High torque oil motor pre-plasticizing drive

2) Five fulcrum and double bent axle locking mould

3) Oil motor drive gear adjusting mould

4) automatic lubrication system

5) Pressure, flow precision running

6) High quality oil pump

7) Injection many stages pressure, speed adjusting

8) Chinese and English computer controlling

9) Mould group data memory function

| Model | Shot Weight | Space Between Tie Bars | Model | Shot Weight | Space Between Tie Bars |

|---|---|---|---|---|---|

| HJF118 | 165grams | 370mmx370mm | HJF580 | 2495grams | 870mmx820mm |

| HJF140 | 236grams | 420mmx420mm | HJF650 | 3108grams | 905mmx890mm |

| HJF180 | 314grams | 480mmx480mm | HJF780 | 3932grams | 1010mmx980mm |

| HJF200 | 388grams | 500mmx470mm | HJF1000 | 4765grams | 1120mmx1080mm |

| HJF240 | 534grams | 530mmx510mm | HJF1300 | 6925grams | 1260mmx1160mm |

| HJF290 | 779.9grams | 600mmx600mm | HJF1400 | 7983grams | 1350mmx1250mm |

| HJF360 | 1026grams | 680mmx680mm | HJF1660 | 10612grams | 1500mmx1400mm |

| HJF400 | 1430grams | 725mmx725mm | HJF2000 | 13356grams | 1650mmx1500mm |

| HJF530 | 1788grams | 820mmx820mm | HJF3000 | 39953grams | 1900mmx1750mm |

| Name | Brand |

| Computer | KEBA(AUSTRIA) ,EST,Techmation,Porcheson |

| Servo Drive | INOVANCE(CHINA),Detal |

| Servo Pump | SUNNY(USA) / SUMITOMO(JAPAN),VICKERS |

| Servo Motor | PHASE(ITALY) |

| Electro-hydraulic Proportion valve | HNC (Taiwan) |

| Stroke transducer | NOVO or Miran(GERMANY)/GERFRAN(ITALY) |

| Breaker | Schneider (FRANCEN)/Siemens(GERMANY) |

| Contacts | Schneider (FRANCEN)/Siemens(GERMANY) |

| Switch | Schneider (FRANCEN)/Siemens(GERMANY) |

| Hydraulic Direction Valve | Vickers (USA) or Rexroth (GERMANY) |

| Plasticing Motor | DINAMIC(ITALY) or STF(ENGLAND) |

| Hydraulic Hose | MANULI(ITALY)/CONTINENTAI(GERMANY) |

| Plasticing speed sensor | OMRON |

| Sealing ring | HALITE or TREIIEBORG(UK or GERMANY) |

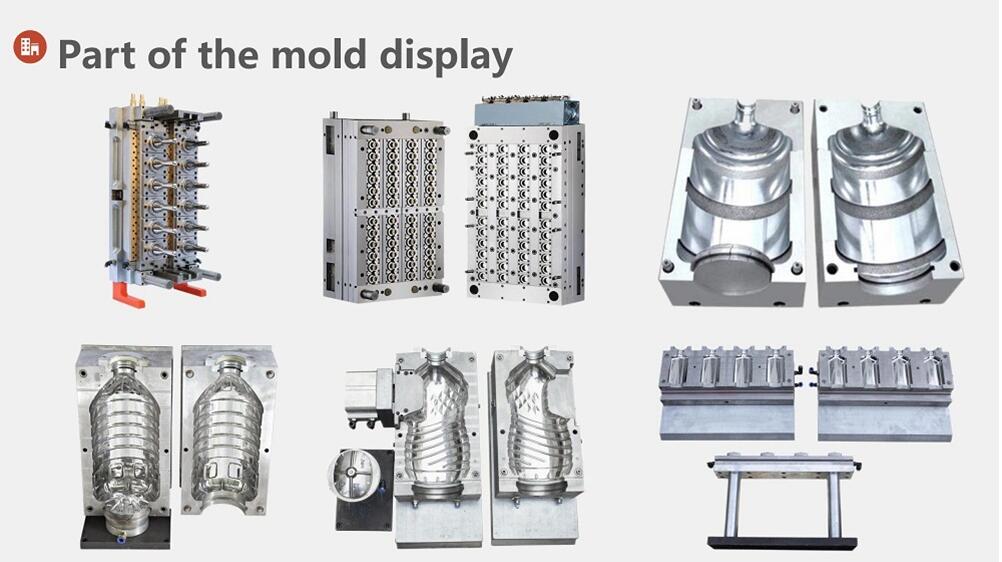

Features of parts of plastic pet bottle making machine

| 1 | LCD computer control with big display screen |

| 2 | Pressure-flow proportional valve. |

| 3 | Hard chrome plated high tensile strength steel tie bars |

| 4 | Generous space for fitting large moulds |

| 5 | Large opening stroke. |

| 6 | Two transducers to control Clamping and Injection |

| 7 | Four stages of injecting, independent velocity and pressure control. |

| 8 | Hydraulic mould height adjustment device. |

| 9 | Screw cold-start prevention device. |

| 10 | Melt decompression control. |

| 11 | Screw back pressure control |

| 12 | Multiple hydraulic ejections. |

| 13 | Differential area high speed clamping. |

| 14 | Centralized lubrication system. |

| 15 | Low pressure mould protection device |

| 16 | Mechanical safety interlock |

| 17 | Double electrical safety interlock |

| 18 | Oil return filter |

Application:

The machines applicable industries include general houseware, electronic products, auto parts, packaging, toys and building components etc.

Q & A:

Q1: How to calculate injection molding machine tonnage ?

If you need,please contact us,our engineer will show you the details.

Q2: How many types of injection moulding machine ?

There many different types machine.BMC injection molding machine,bakelite injection molding machine,desktop injection molding machine,

injection molding machine gas,injection molding machine vertical,injection molding machine small.

Q3:How much is a plastic injection molding machine ?

Small one injection molds not expensive.only big mold cost much money.

Q4:what is injection molding machine?

It is a machine can make plastic pellet into plastic products like,plastic cap,plastic lid,plastic bucket,plastic pot etc.

Q5: How to make injection moulding machine ?

Need assembly engineer,assembly it follow drawing.

Q6:How to buy injection molding machine?

Check the weight and size of your plastic item.then tell the Injection molding machine manufacturer. They will suggest a suitable model machine to you.

Q7:How much do injection molding machines cost ?

90 tons injection molding machine is a small machine. not expensive. you can send inquiry to us.we will send quotation to you.

Q8:what is plastic molding machine?

It can make plastic items