Fully automatic plastic box making machine

There are many different kinds of box machine on market, say: apple box making machine,packing box making machine,industrial box making machine,biodegradable lunch box making machine,egg crate making machine for sale.But most of them is plastic injection molding machine.

HAIJIANG is a China injection moulding machine manufacturer, which supply all kinds of plastic injection molding machines from 50T to 3000T.His HJF240 model is good food container box making machine. because most of food container box is thin wall,require big clamping force and high speed machine.It is a best small box machine.Machine box cost must be less. because food container sold by a very low price.

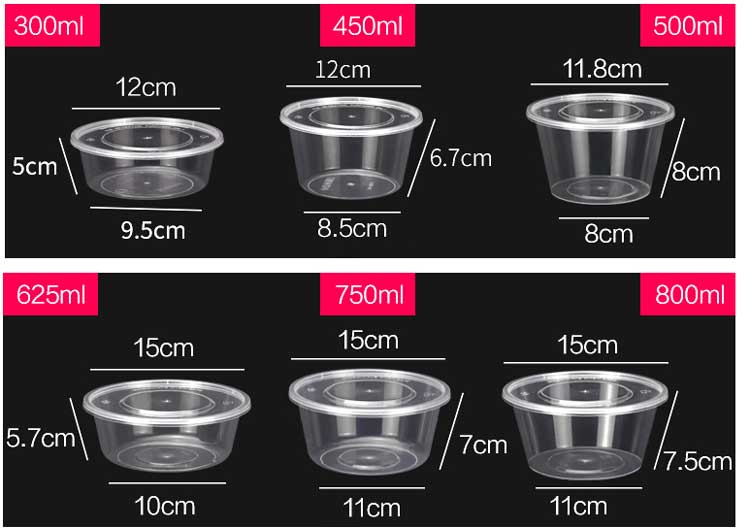

Auto box maker usually buy such size injection molding machine to make disposable food container.

Automatic box maker know the box making machine price.Made in China is less than Japan or Germany.

There are many used box making machine for sale in South Africa too.Box making machine uk brand is few.

So,all over the world,70% plastic food container making machine From China.

7. Injection End and temperature tracking is curve display, dynamic recorder parameter is modified, dynamic warningis exhibited, all these make the operation more convenient.

Egg tray making machine manufacturers in india bought more than 10 sets plastic injection molding machine from Haijiang. They made one copy egg tray tray making machine project report.They told us there is very big market for egg tray. India, the second biggest Populous country. Every day, consume lots of eggs.

Disposable food container making machine Servo Controller Part

5. Water cooling saving The system condition prevent high pressure uploading without any power output, leads to the water cooling saving.

Plastic container making machine price in india is not expensive too.Except sweet packing box making machine,Haijiang HJF360,HJF400 and HJF530 are good for making plastic crate. Plastic crate making machine price is much more than food container making machine.Right size box maker will buy fruit basket making machine,takeaway food container making machine,disposable plastic food container making machine.There are big demand for these machine.Plastic bucket making machine price in india is little high than China.

Pls tell me your product's production capacity even your financial budget , we'll provide you a satisfactory solution with competitive price !