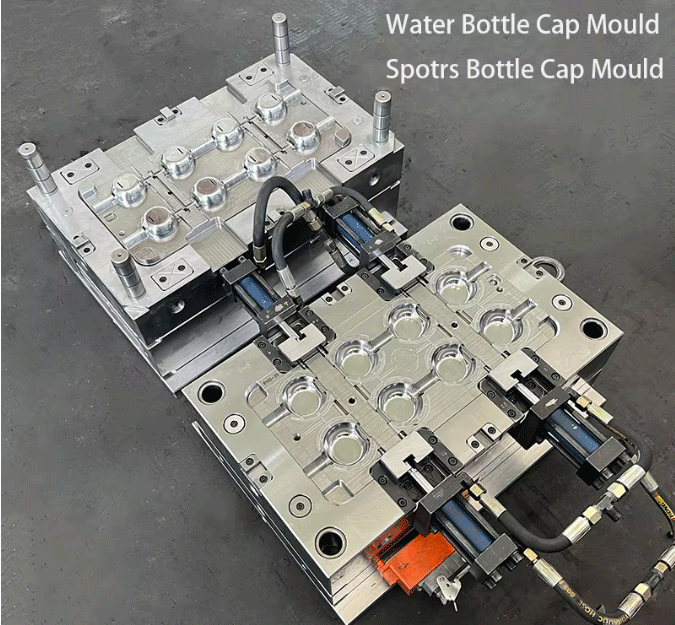

8 Cavities Juice Bottle Cap Plastic Cap Mould

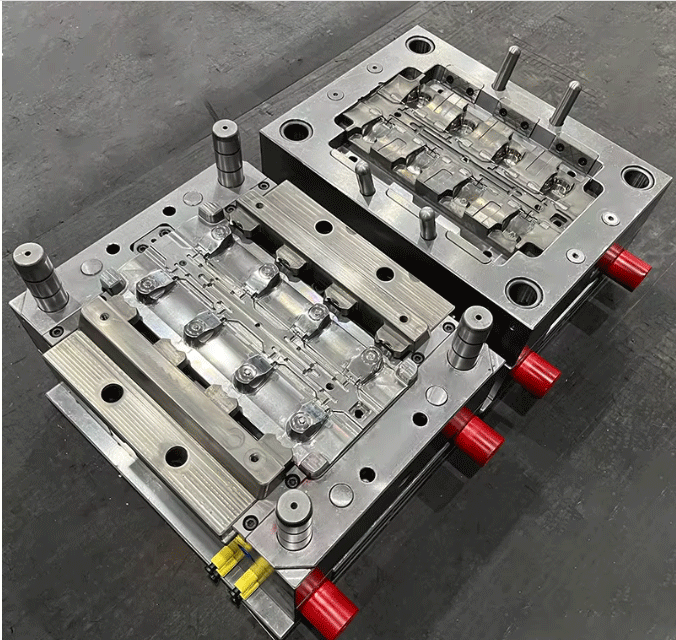

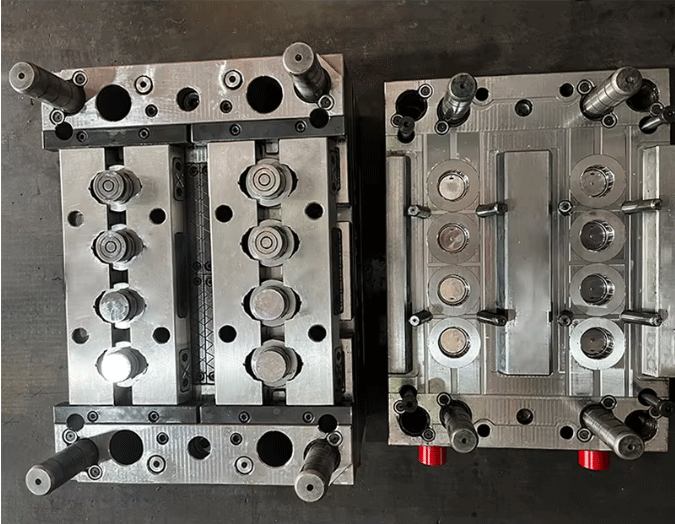

We is specialized in plastic bottle cap mould manufacturing. We are good at different types of caps, includes Flip top caps mould, Mineral water cap mould, Screw cap mould, Jar lid mould, Pull-push cap mould, 5 gallon bottle cap mould, Oil bottle cap mould as well as other custom cap injection mold.

At haijiang, the available cap mould cavity number is from one cavity up to sixty-four cavities. We will suggest the suitable cavity number according to customers' cap design and injection machine size.

Process of Cap Mould Manufacturing

1. Bottle Cap Design

2. Cap Mould Design

3. Cap Mould Manufacturing

4. Cap Mould Trial

5. Water Leakage Testing

6. Mould delivery

Why Haijiang Mould for Plastic Cap Injection Molding?

We understand that the mould quality is the top concerns for all customers. Keeping that view in mind, our team focus on every steps from mould design, making and delivery.

Our factory always adopst high strength steel material to make bottle cap mold. The hardness of steel is generally more than HRC45. We use high-speed CNC machining center to process molds and carry out standardized operations, to ensure the accuracy of the parts of each bottle cap mold and achieve the interchangeability of each part.

During the mould manufacturing poried, we will report and update the mould status every wekk to customers. And we have a reputation for always meeting deadlines and dlivering mould on time.

If you want to buy pet bottle cap mould,5 gallon cap mould,plastic bottle cap mold,screw cap mould,bubble cap mould, you can contact us. we can design it for you fast. You can do injection molding bottle caps as soon as possible. We also have cap injection molding machine. After you fixed the plastic bottle cap mould on the injection moulding machine,then you can start your cap making business.

| Product Name | 8 Cavities Juice Bottle Cap Plastic Cap Mould |

| Mould Steel | P20H,718H,2738H,S136,H13 etc. |

| Product Material | PP,HDPE,LDPE etc. |

| Mould Base | LKM,ISM,HASCO,DME |

| Cavity | Single/Multi-cavity |

| Mould life | 500,000 ~1million shots |

| runner type | cold/hot runner |

| Delivery time | 30~60day |

| The main Mold Steel and Hardness for you reference: | ||||||||

| Steel Grade | S50C | P20 | P20HH | 718H | 2738H | H13 | S136 | NAK80 |

| Hardness(HRC) | 17-22 | 27-30 | 33-37 | 33-38 | 36-40 | 45-52 | 48~52 | 34-40 |

FAQ

Q: 1 Are you trading company or manufacturer ?

A: We are cap mould factory.if you need bottle cap injection moulding machine or cap compression moulding machine price,we can send a good offer too.As a plastic cap mould manufacturers. we can give you pvc cap mould,flip cap mould,flip cap mould design too.There are many customer like chemical bottle cap mould,usually,the cap is dark color.But the plastic cap mould design is the same. just mix some colormaster intot the plastic raw material like PP,PE. then you can moulding cap color as your like.

Q: 2 Where is your factory located?

A: Our factory is located in Yinzhou,Ningbo city, Zhejiang Province, China.45 minutes from Ningbo airport by car, 15 minutes from train station to our factory.If you are looking for a china bottle cap mould maker or manufacturer.please feel freely contact us.once you need speedo moulded silicone cap,you can send us speedo plain moulded silicone cap sample or drawing.we can design mold for you too.

Q: 3. How to go to your factory?

A: You can come to our city by flight, bus or train.

It takes 2 hours by flight from Guangzhou to our city.

It takes 3.5 hours by train from Shanghai to our city.

It takes 1 hour by bullet train from Ningbo to our city.

Q: 4.How about quality control in your factory?

A: We believe "Quality is above everything". We have professional team to control the quality. Our QC team mainly do the following procedures:

A) Design Optimize control

B) Mould steel hardness Inspection

C) Mould assembly Inspection

D) Mould trial report and samples Inspection

E) Final inspection for mould & packing before shipmentIf you have another question, pls feel free to contact us as below:

Q:5. If i provide you 3d drawing of my product, can you quote the price & make the mould as per the 3d drawing?

A:Yes. we can do plastic cap moulding for you too.Also have rotary cap compression moulding machine.

DWG, DXF, STEP, IGS and X_T files can all be used to quote price, make mould as per your models - This can save time and money in producing your parts.we can offer bottle cap mould design for you choosing too.and choose the correct cap moulding machine size for you.Help you become a excellent cap mouder.

Q: 6. What type of plastic material is best for my design/component?

A: Plastic Materials selection depends on the application of your product. We will give you some suggestion after we checked the function of your component. And we can make the mould trial with different material according to your requirement.

Q: 7. What kind of mould can you make?

A: We can make all kinds of plastic injection moulds and blow moulds,like water bottle cap mould.

We can suggest you the proper cavity number as per your injection machines sizes.

Q:8. What's your payment method?

A: By T/T, L/C, Trade Assurance, Western Union.

Q:9. How long of your mould delivery time?

A: It takes 6-10 weeks to have the mould manufactured depending on the mould structure and the number of cavity (single or multi) after you approved our mould drawing. The delivery time should be calculated from the date you approved our mould drawing. We can ship your plastic moulds with 1 week after you confirmed our final samples.