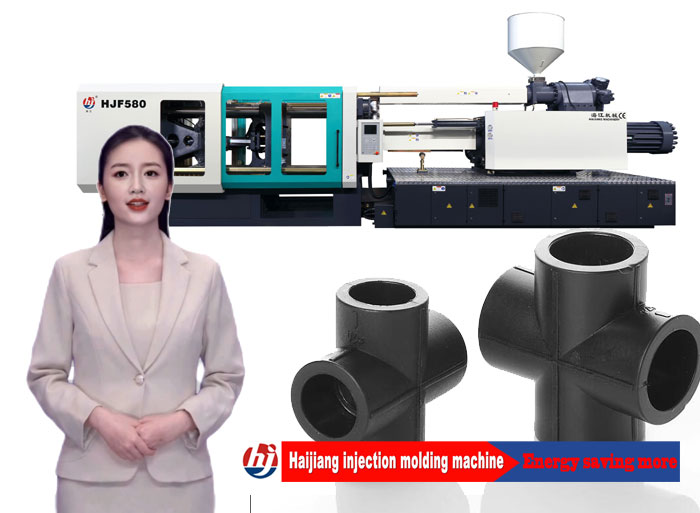

Sure! Here's detail of a pvc injection molding machine:

A PVC injection molding machine is a machine that uses heat and pressure to form plastic objects from PVC (polyvinyl chloride) pellets. The machine has two main components: an injection unit and a clamping unit.

The injection unit heats the PVC pellets and forces them into the mold cavity under high pressure. The clamping unit holds the mold cavity closed while the plastic is injected and allowed to cool and harden. Once the plastic has cooled and hardened, the mold is opened and the plastic object is ejected.

PVC injection molding machines are used to produce a wide variety of plastic objects, including pipes, fittings, window frames, and consumer products.

Here are some of the advantages of PVC injection molding:

- It is a versatile process that can be used to produce a wide variety of plastic objects.

- It is a relatively fast process that can produce high volumes of products.

- It is a precise process that can produce objects with high dimensional accuracy.

- It is a cost-effective process that can produce high-quality products at a competitive price.

Here are some of the disadvantages of PVC injection molding:

- It requires a significant initial investment in equipment.

- It requires skilled operators to operate the equipment.

- It can be a hazardous process if not properly operated.

- It can produce waste products that need to be disposed of properly.