Ceramic injection molding (CIM) is a manufacturing process that is used to produce complex, high-precision ceramic parts and products. A ceramic injection molding machine is a specialized machine that is designed specifically for this process.

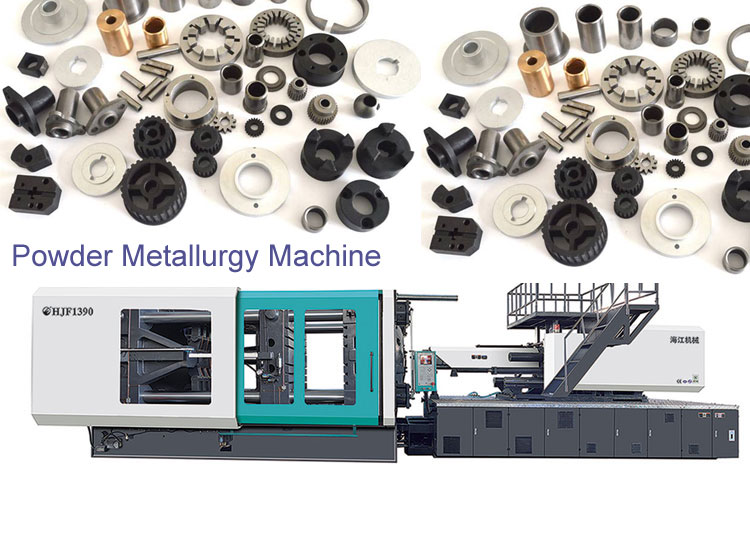

Ceramic injection molding involves injecting a slurry of ceramic powder and binder into a mold under high pressure. The slurry is then cured and cooled, and the resulting ceramic part is removed from the mold.

Ceramic injection molding machines are highly specialized machines that are designed to produce high-quality ceramic parts and products using the CIM process. They offer a number of benefits, including fast cycle times, high production rates, and low scrap rates, which make them an ideal choice for a wide range of applications.

Ceramic injection molding is often used in the production of high-precision ceramic parts and products, such as medical implants, electronic components, and automotive parts. It offers a number of benefits, including the ability to produce complex, detailed parts with high precision and efficiency.

Ceramic is a type of inorganic, non-metallic material made from clay and other compounds. Ceramics are known for their high strength, durability, and resistance to heat, wear, and corrosion. They are used in a wide range of applications, including construction, automotive, aerospace, and medical.

There are many different types of ceramics, including:

Clay ceramics: Clay ceramics are made from clay and other minerals, and they are known for their high strength and durability. Examples of clay ceramics include bricks, tiles, and pottery.

Glass ceramics: Glass ceramics are made from a mixture of glass and ceramic materials, and they are known for their high strength and resistance to heat and wear. Examples of glass ceramics include cookware, glass-ceramic stovetops, and fireplace tiles.

Technical ceramics: Technical ceramics are high-tech materials that are used in a variety of applications, including aerospace, automotive, and medical. Examples of technical ceramics include silicon carbide and alumina.

Overall, ceramics are an important class of materials that are known for their high strength, durability, and resistance to heat, wear, and corrosion. They are used in a wide range of applications, and they offer a number of benefits, including high performance and reliability.